Predictive Maintenance Dashboard

The Challenge

Sensors were already installed on the production floor, but data landed in isolated vendor dashboards. Maintenance supervisors lacked a single view to prioritise work orders across three sites.

Our Solution

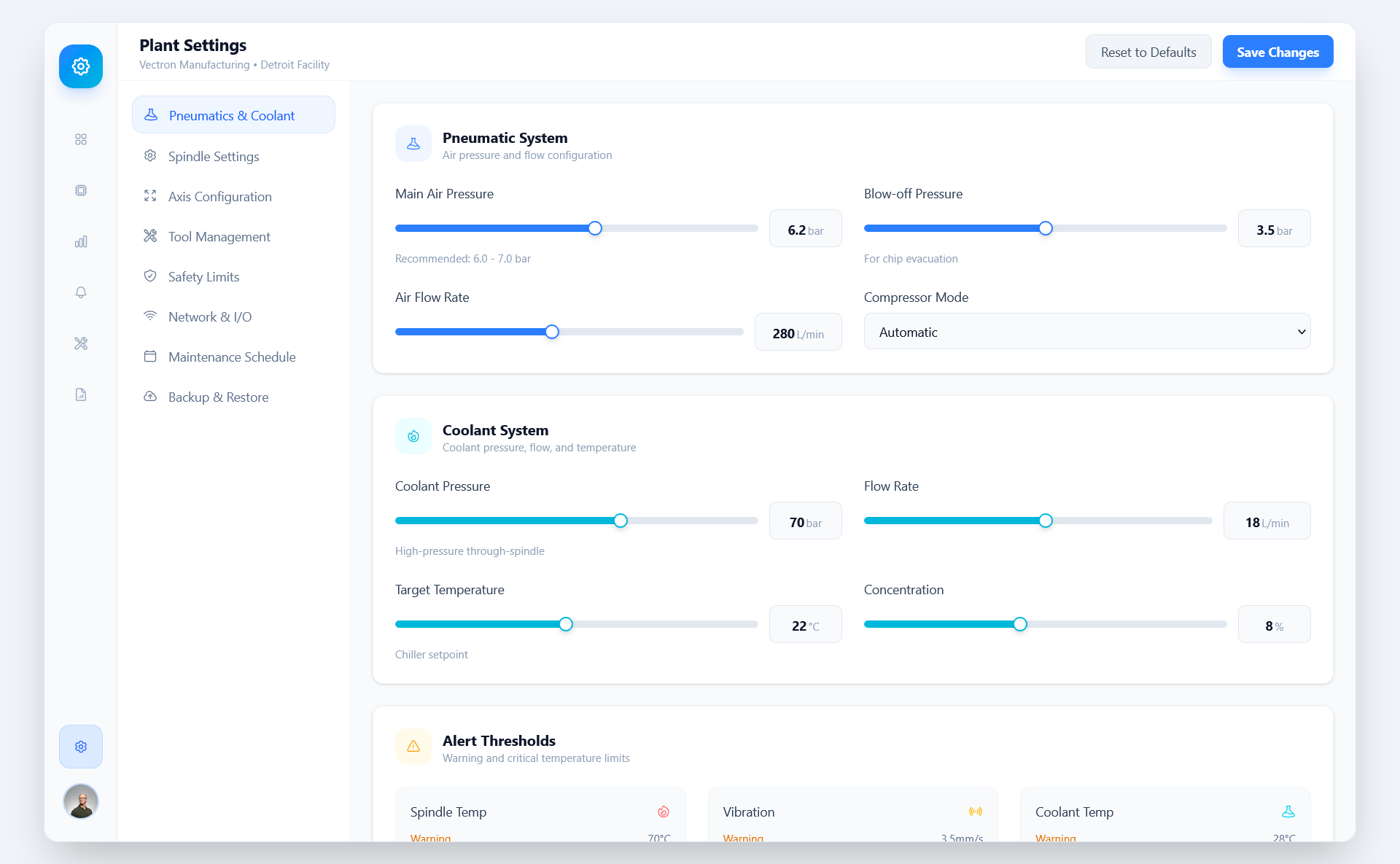

We built a time-series ingestion pipeline, normalised telemetry, and surfaced anomalies that correlate with historical breakdowns. Maintenance tickets are raised automatically in Microsoft Dynamics when thresholds are exceeded.

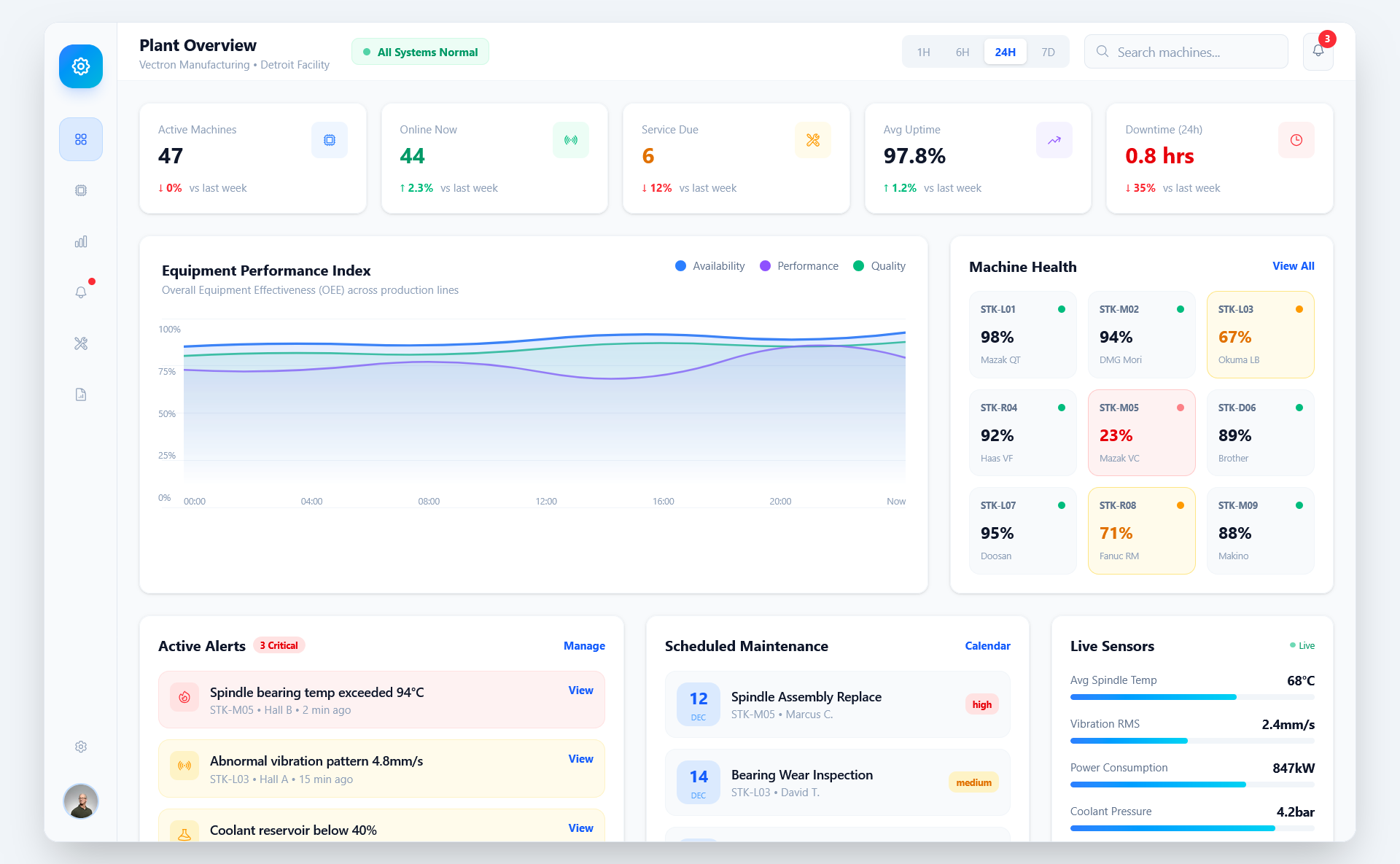

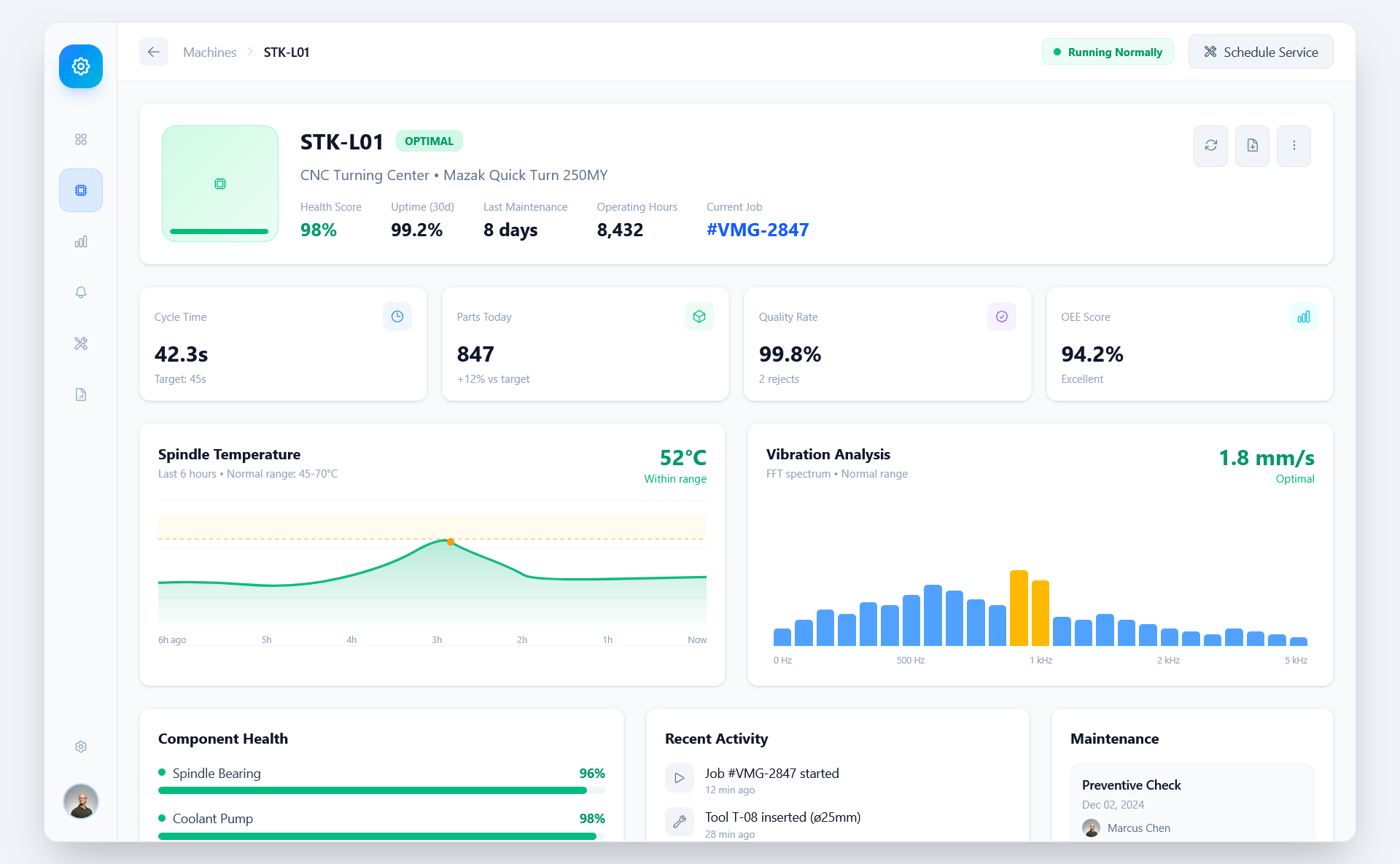

Key Features Delivered

- Streaming ingestion with device-level health scores

- Mobile-friendly dashboard for technicians on the floor

- Automatic ticket creation in Microsoft Dynamics 365

- Historical playback to validate recommended actions

Project Gallery

Explore the project visuals

Technology Stack

Powered by industry-leading technologies

Business Impact

Unscheduled stoppages dropped by a third during the first six months, and weekly stand-ups now revolve around a shared dashboard instead of anecdotal reports. Leadership finally has visibility into equipment utilisation across all facilities.

Project Timeline

Assessment & Data Review

3 weeks

Mapped telemetry sources, validated data quality, and agreed on alert thresholds.

Pipeline & Modelling

6 weeks

Normalised sensor data, created anomaly detection models, and produced baseline dashboards.

Application Build

5 weeks

Developed the Vue front-end, device overview screens, and technician task list.

Rollout

4 weeks

Piloted in the Gothenburg plant, gathered feedback, and expanded to remaining sites.

"The dashboard gives us a calm overview of what actually needs attention. We no longer firefight—we plan our maintenance windows with data on the table."

Ready to Transform Your Business?

Let's discuss how we can help you achieve similar results

Related Projects

Trusted By Industry Leaders

Proven Track Record of Excellence

Delivering AI-powered solutions to enterprises worldwide with measurable ROI and lasting impact